Table of Contents

Advertisement

Save

This

Manual

For Future

Reference

MODEL

NO.

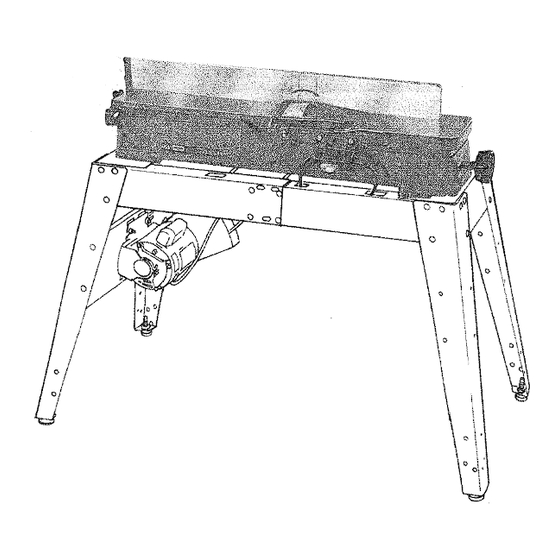

113,206801

JOINTER/PLANER

ONLY

113.206931

JOINTER/PLANER

WITH

LEGS AND MOTOR

Serial

Number

Model

and serial

number

may be found

on a plate attached

to your

base.

You should

record both

model and serial

number

in a safe place for

future

use.

CAUTION:

Read

GENERAL

and

ADDITBONAL

SAFETY

aNSTRUCTIONS

carefully

6 -INCH

JO/N TER-PL A NER

• assembly

o operating

• repair parts

Sold by SEARS,

ROEBUCK

AND

CO.,

Chicago,

IL

60684

U.S.A.

Part No. 67037

#,_._._

_bS._

Advertisement

Table of Contents

Summary of Contents for Craftsman 113

- Page 1 CAUTION: Read GENERAL ADDITBONAL SAFETY aNSTRUCTIONS carefully Sold by SEARS, ROEBUCK Part No. 67037 6 -INCH JO/N TER-PL A NER • assembly o operating • repair parts CO., Chicago, 60684 U.S.A.

- Page 2 general safety 1. KNOW YOUR POWER TOOL Read understand the owner's affixed tool. Learn limitations as well as the specific peculiar to this tool. 2. GROUND ALL TOOLS This tool is equipped with an approved cord a 3. arong grounding type 3roper grounding...

- Page 3 ACCORDING TO THE INSTRUCTIONS YOU HAVE READ AND UNDERSTOOD ING. 1. GENERAL SAFETY INSTRUCTIONS TOOLS 2. GETTING TO KNOW YOUR JOINTER-PLANER 3. BASIC MACHINE OPERATION 4. USE OF HOLD-DOWN/PUSH BLOCKS 5. MAINTENANCE 6. STABILITY OF MACHINE if there is any...

- Page 4 MATERIAL 3 INCHES PLANING MATER_AL THINNER THAN tool result foreign eyes, which can result wear safety goggles complying on Package) before commencing Goggles are available at Sears YOUR JOINTER-PLANER O PERATION Blocks Blades Guard Spr=ng ... Cutter Blades ACCESSORIES THIS...

-

Page 5: Motor Specifications And Electical Requirements

motor specifications This machine is designed to use a 3450 Do not use any motor that runs faster It is wired operation on 110-120 volts, nating current. MUST OPERATE VOI.TS, EVEN THOUGH RECOMMENDED MOTORS THESE CRAFTSMAN MOTORS FOUND TO BE ACCEPTABLE THIS TOOL. - Page 6 7/]6_i Wrench 1121 Wro=" 3/41Wre.ch " " 3/8' Wrench Model 113 206801 Jointer/P aner is shipped complete one carton but DOES INCLUDE Steel Legs, or motor. Model: 113,206931 JointerlPlaner is shipped one carton but INCLUDES Steei Legs, and Motor.

- Page 7 TABLE OF LOOSE PARTS The Following Parts Are included Model 113.206931 Only Item Description End Stiffener Side Stiffener Motor Support Motor Package of Miscellaneous Small Parts, No. 67035, Consisting of the Following: Cord Clip Hex Nut, 1/4 in. - 20 (approx.

- Page 8 parts, 18 x 3/4 7 Washers; 11/32 ID 7 Hex Jam NUts, 5/16-18 2 Cord Clips 2. Loosen FENCE LOCK KNOB. Tilt fence J_toward pulley. 3. Position machine on Leg Set and align m machine with holes Leg Set letter Mount with three...

- Page 9 MOTOR BELT GUARDS Seepage5 for recommendedmotors. PARTS NEEDED 4 carriage bolts, 5/16-t8 x 3/4 in., washers and nuts. 1 Jointer Planer Belt Guard Motor Pulley Belt Guard Belt Guard Support Belt Guard Support Bracket i,,pl Place motor on your workbench...

- Page 10 osse :::shaft h_bl fi_,_ with CHECK MOTOR ROTATION T_,_ m_ m_,_ rotate COUNTERC{.OCKWiSE whe_ Wewed PL_LL£Y end_ 1L Piaee motor or_ your workbench or on floor. 2. Stared clear motor and plug 9rounded outlet (See pa_¢ 5). f_}otice r_tation If it is not tutoring COUNTERCLOCKWISE, plug from...

- Page 11 Loo_mn _k'm two _i_OTOR BASE Ct &MP moto_ sidewav_ u_-li nlotOr pu_!ev putter (>n _he £_achb_, ir_sta!i V,_¢}t _:iP, d PUSH dow!-_ {:,_ t_nson t)_it tqbteu_ mouatin 9, boils. NOTE: _t is oqly necessary a_sply be!t preve_t pkI{Jey5 W_ii8 * Uf'l_31f'_t}, t:,_ A_t_ r:_oto_...

-

Page 12: Fence Locks And Stops

FENCE SLIDE 8RACKET 1, DEPTH OF CUT HANDWHEEL. handwheel counterclockwise will table to maximum depth Of !/8,.in, FENCE LOCKS STOPS. moved acrossthe Jointer to take full advantage of the "sharpness" of the blades. The fence should be positioned to the extreme right (toward pulley) but not beyond the end of the blades. -

Page 13: Fence Tilt Scale

b. Before tightening fence lock knob, down outfeed table 90 ° Fence Stop positions fence To tilt fence, loosen the two knobs stop out. Tilt to desired angle knobs. d. To fence at 90 ° tables, knobs, tilt fence so the stop place. -

Page 14: Infeed Table

to know your e.: Adjust 45 ° stop same manner, NOTE: Tilt scale will not require was adjusted for 90 ° position. CUTTER GUARD, Provides protection cutter head. It must always be in place and function- ing properly. Check the guard to make sure it is functioning perI¥. - Page 15 a, Insert a pencit in space at end of cutterhead hold cutterguard open, b, Place a straightedge (large square outfeed table, First along one side than other, Raise infeed table until touches d, Sight between table and straightedge high condition It is easier to adjust the infeed table while...

-

Page 16: On-Off Switch

THIS FEATURE INTENDED UNAUTHOR IZED HAZARDOUS CHILDREN OTHERS, a. _lnsert Key into switch. NOTE: Key {s made of yellow plastic, your loin er planer with 1/2 in.- LEVELING STUDS VIEW LOOKING or LOWER studs until T1GHTEN Screws tight. make sure... - Page 17 b, To turn machine insert finger lever and pull end of switch out. c. To turn machine OFF... PUSH lever in. Never leave machine unattended until to a complete stop. d. To lock switch in OFF position.., with one hand,. , REMOVE key with WARNING:...

- Page 18 F_)r your own safety ALWAYS use the hold blocks when JOINTING wood that is NAR ROWER 3"in.. _ .o t when PLANING Wood that is TH I N N E R than 3in. Do not plane, joint or bevel wood shorter Material this...

- Page 19 Always feed WITH GRAIN whenever nature of the workpiece is such that AGAINST GRAIN, take very light slowly, USING THE HOLD DOWN!PUSH BLOCKS ALWAYS use the hold down/push blocks wood that is NARROWER than 3 in. or wood that is thinner than 3 in.

- Page 20 NEVER ATTEMPT PERFORM OPERATION ON THIS JOINTER. DO NOT OPERATE JOtNTER/PLANER WITH CUTTERHEAD GUARDS REMOVED. Rabbet cuts should be made on the Radial Saw or Table Saw b_ making two cuts with the sawblade...

-

Page 21: Replacing Cutter Blades

CUTTER BLADES WARNING: YOUR SAFETY. SWITCH "OFF" AND REMOVE PLUG FROM POWER SOURCE OUTLET BEFORE ADJUSTING, MAINTAIN- ING, OR LUBRICATING YOUR JOINTER-PLANER. 1. Remove belt guard, 2. Position fence right . , . approximately beyond cutter blades . . . lock... - Page 22 +003 average piece of paper). NOTE: Sears has a knife setting gauge for this purpose. Cat. # 9-2647 13. "Now install both locking setscrews 5/32" setscrew wrench) alternately time.

-

Page 23: Installing Cutter Guard Spring

INSTALLINGCUTTER GUARD SPRING 1. Remove cotter pin from pivot pin in cutter remove guard (located underneath Spring must appear as in sketch from feed table, will perform properly upside down. 2. Position guard as shown, with PIVOT in infeed table. 3. - Page 24 5. Replace guard and cotter pin. If guard still does not return to its REST position; sult your local Sears Retail Store before jointer-planer. SHARPENING CUTTER BLADES The blades can be honed individually with an ordinary oilstone.

- Page 25 Keep your jointer-pianer clean, Put a carton of a container underneath your jointer-planer the chips. The container should reach above the top of the motor. allow pitch accumulate fence, the cutter guard, the cutter head or the knives,...

-

Page 26: Troubleshooting

REMEDY parts before using again. Sears Service. Any attempt this motor may create a HAZARD is done by a qualified service Repair service is available at your Sears Store,... - Page 27 CRAFTSMAN 6-1/8 iNCH JOINTER-PLANER FIGURE MODEL No. 113.206801 FIGURE 67033 60314 STD551225 STD541025 67032 62614 62204 67034 STD541250 803835 67035 HARDWARE FOR MOUNTING I STD532507 STD551231 I STD551031 STD523120 _*Nut, eSupplied i£ Loose Standard Hardware AND 113.206931 1 - LEGS PARTS LIST...

- Page 28 SWtTCH BOX ASSEMBLY SEE F_GURE 5 FOR EXPLODED VIEW FIGURE iNFEED TABLE GURE EXPLODED VIEW FENCE ASSEMBLY SEE FIGURE 4 FOR EXPLODED VIEW...

- Page 29 _Wrench Hex, 5/32 60096 Screw Mach., I/4-20 x 1-I/4 455872 Lockwasher 'Standard Hardware "lStoek Item most Sears or S}mpsons-Sears MODEL No. 113.206801 FIGURE 2 PARTS LIST 63410 Knob, 67016 Shaft, STD541031 *Nut, 102832 Screw, 67017 Sleeve STD551025 *Washer, STD551!25 *Washer,...

- Page 30 Bushing STD522505 i Screw, Cap, 1/4-20 STD551025 : Washer, Plain, 17/64 21812 Plate, Tension *Standard Hardware items-- May Be Purchased MODEL No, 113.206801 3 INFEED TABLE PARTS LIST Key! Part No. ! 21422 21219 21218 STD551 21635 STD523112 !:STD551031 21204...

- Page 31 Plain, I3/64 STD510802 *Screw, Mach., No. 8-32 x 1/4, Bind Hd., S_otted 102817 Screw, Set, 1/4-20 x 1/2", Pt., Slotted FIGURE FIGURE 5 MODEL No. 113.206801 FENCE ASSEMBLY Part 21229 STD5512t0 STD511102 x 1-1/4. 67009 STD 533725 21738 STD551037 47624...

- Page 32 REPAIR FOLLOWING INFORMATION: PART NUMBER MODEL NUMBER 113.206801 113.206931 All parts listed may be ordered from any Sears Service Center and most Sears stores. If the parts you locally, your order will be electronically Repair Parts Distribution ROEBUCK CO., Form No.